For the Electro mobility, there will be many challenges in the near future, and Cisel is ready to support this epochal change.

Thanks to years of experience and high technological know-how Cisel is able to assume a leading role in the “electric revolution” in progress.

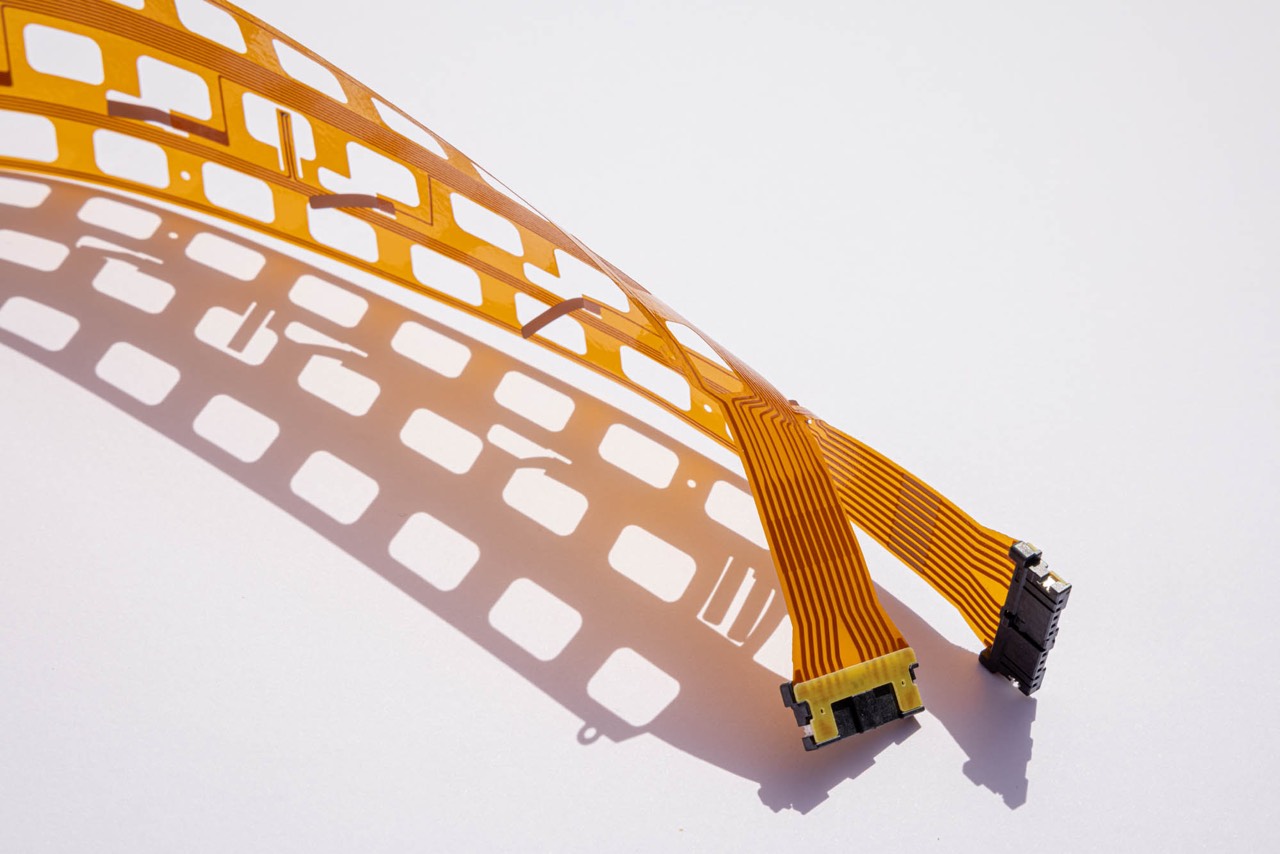

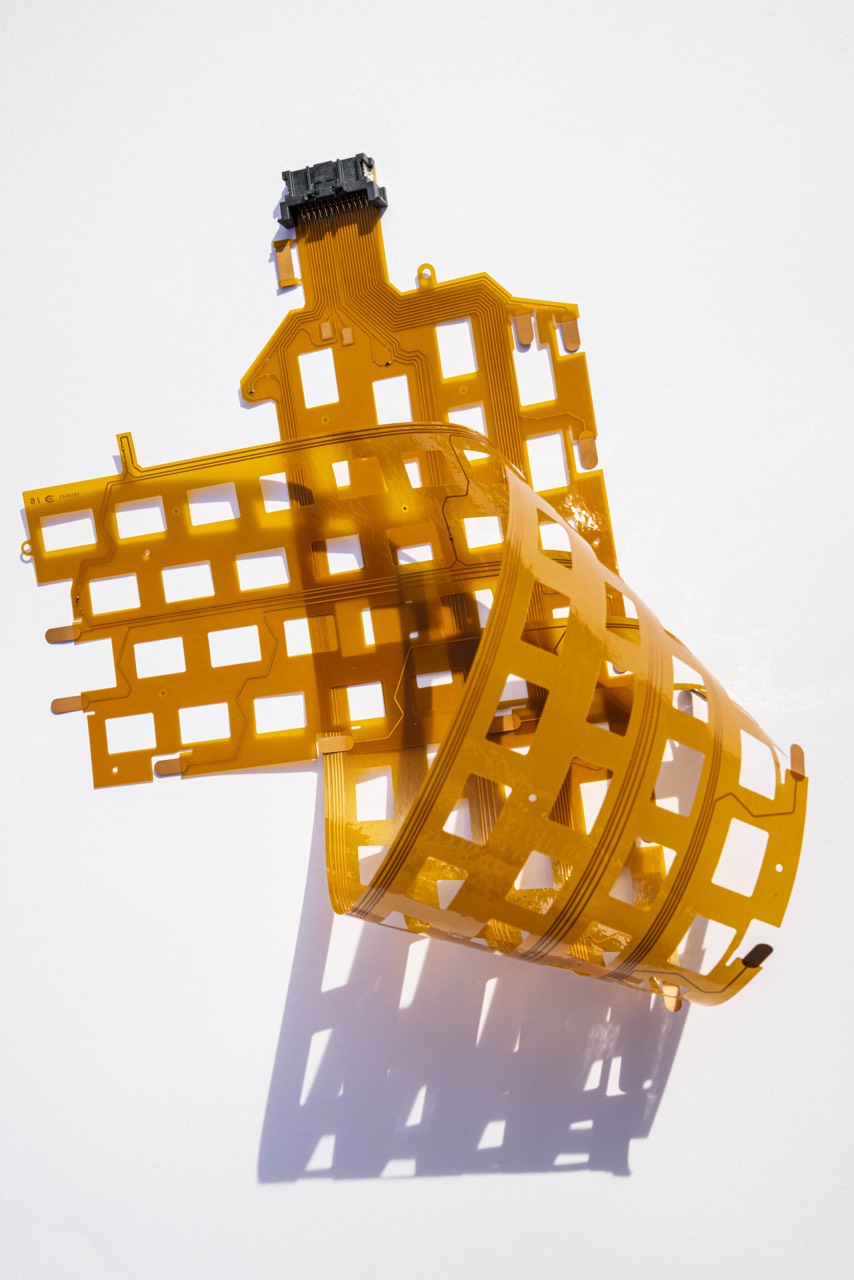

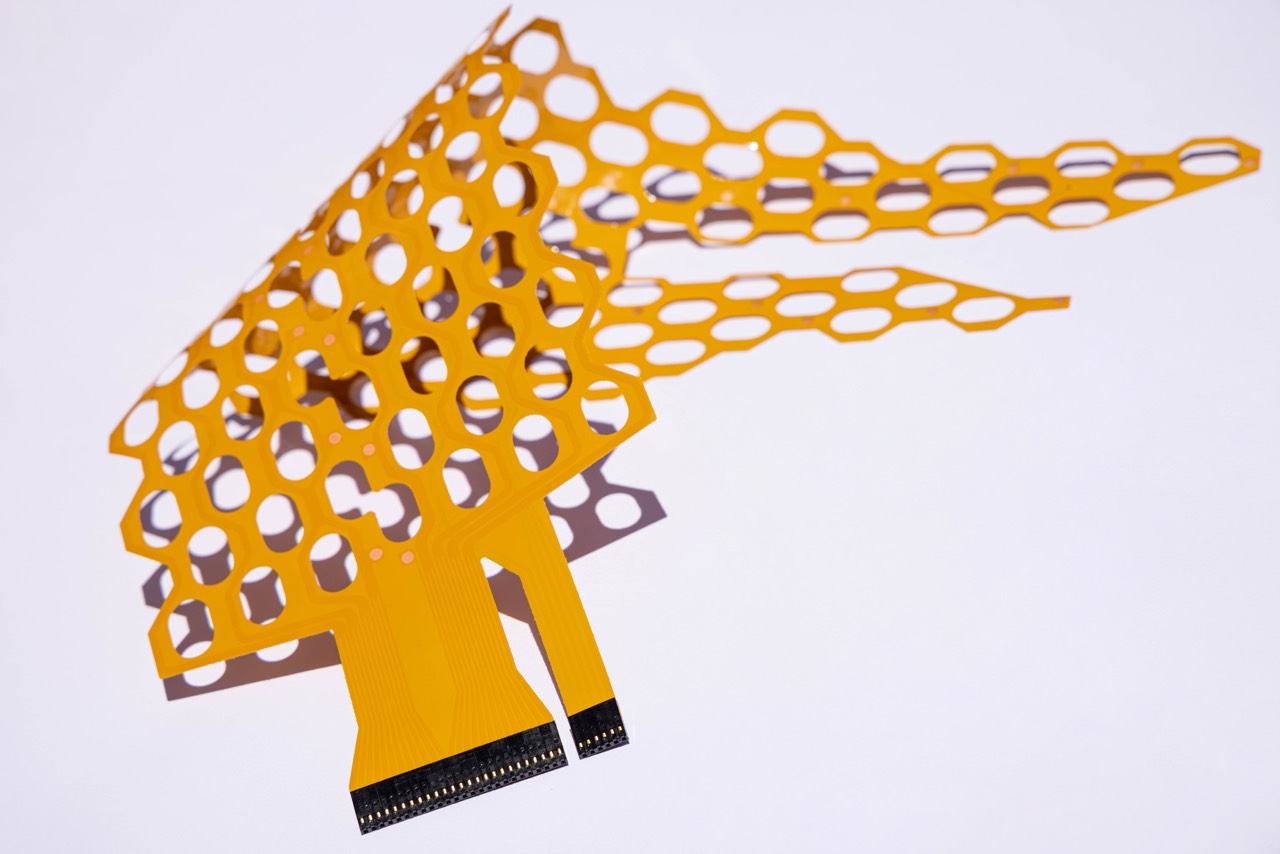

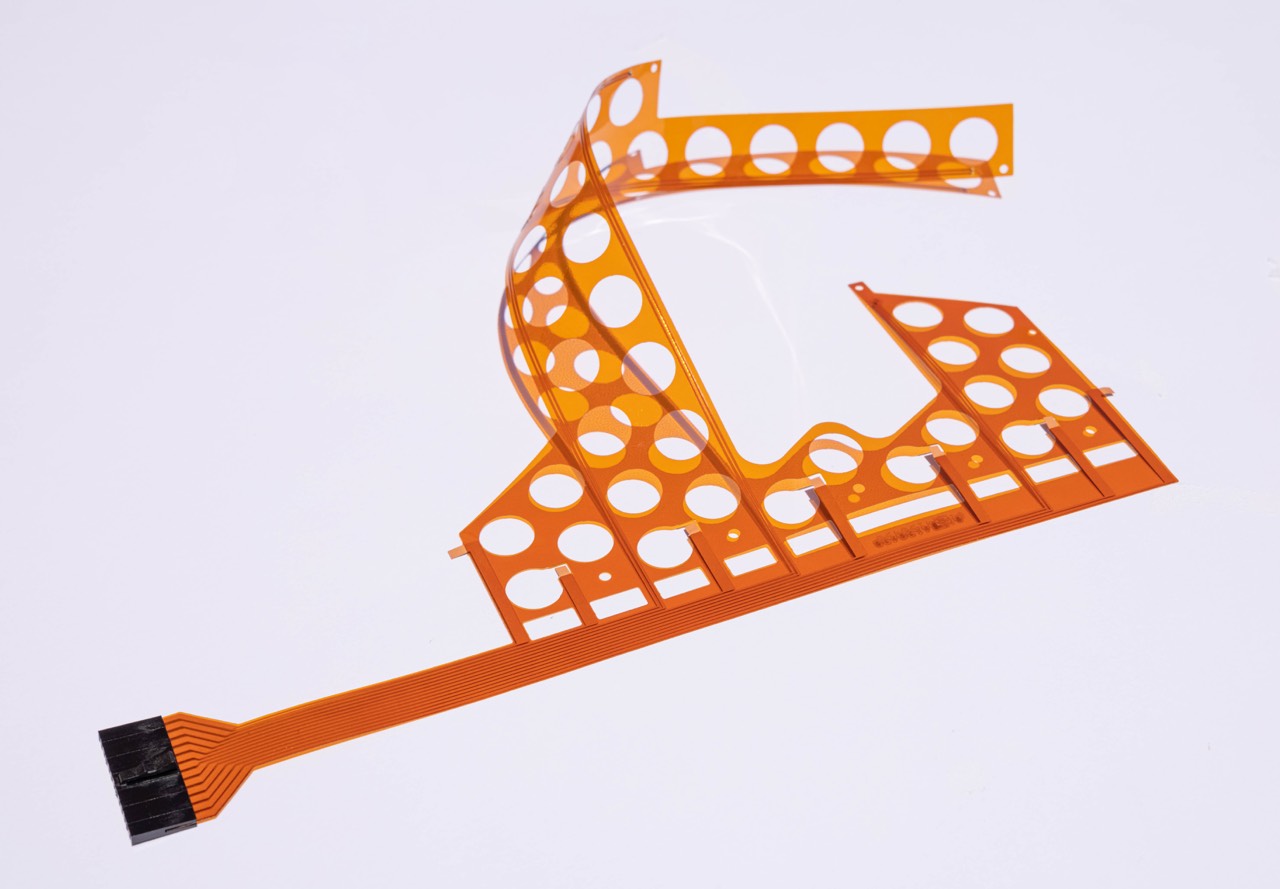

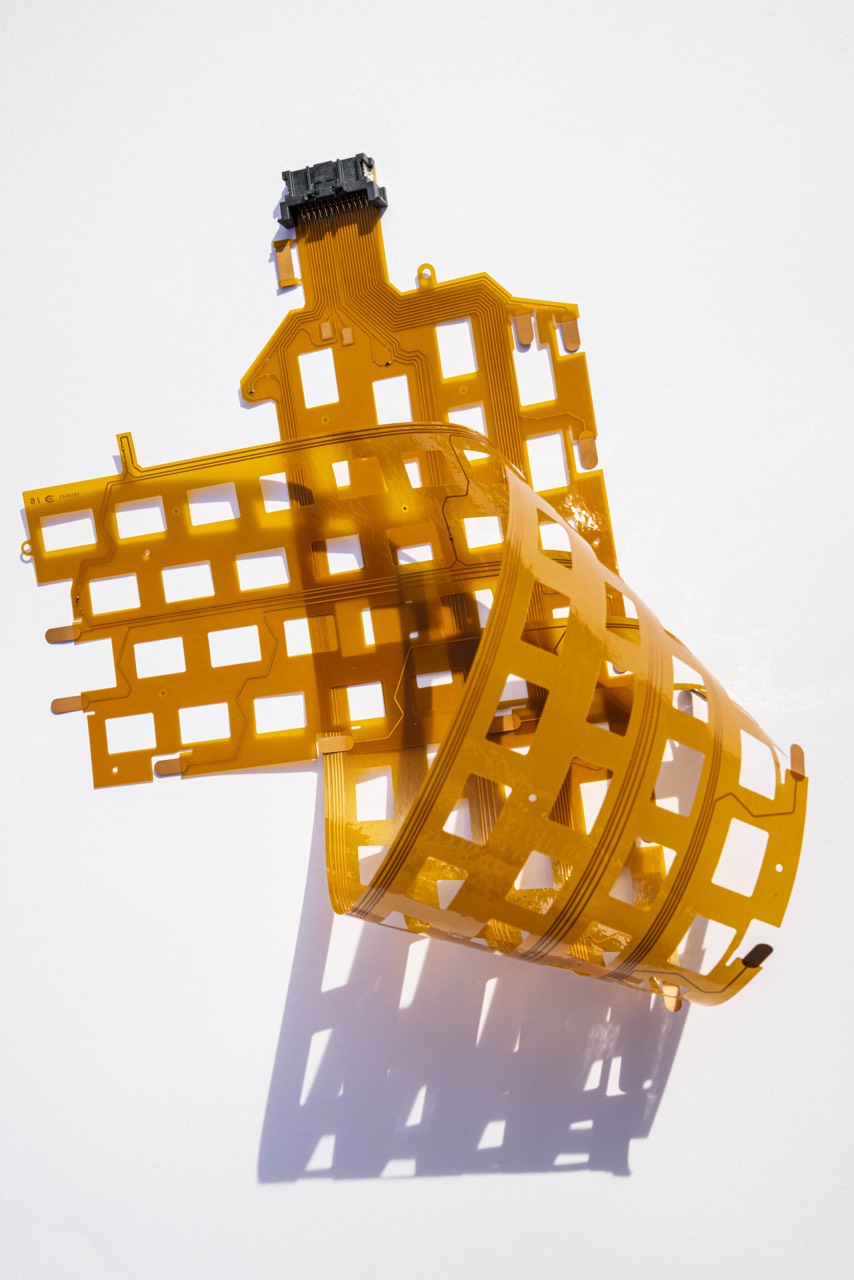

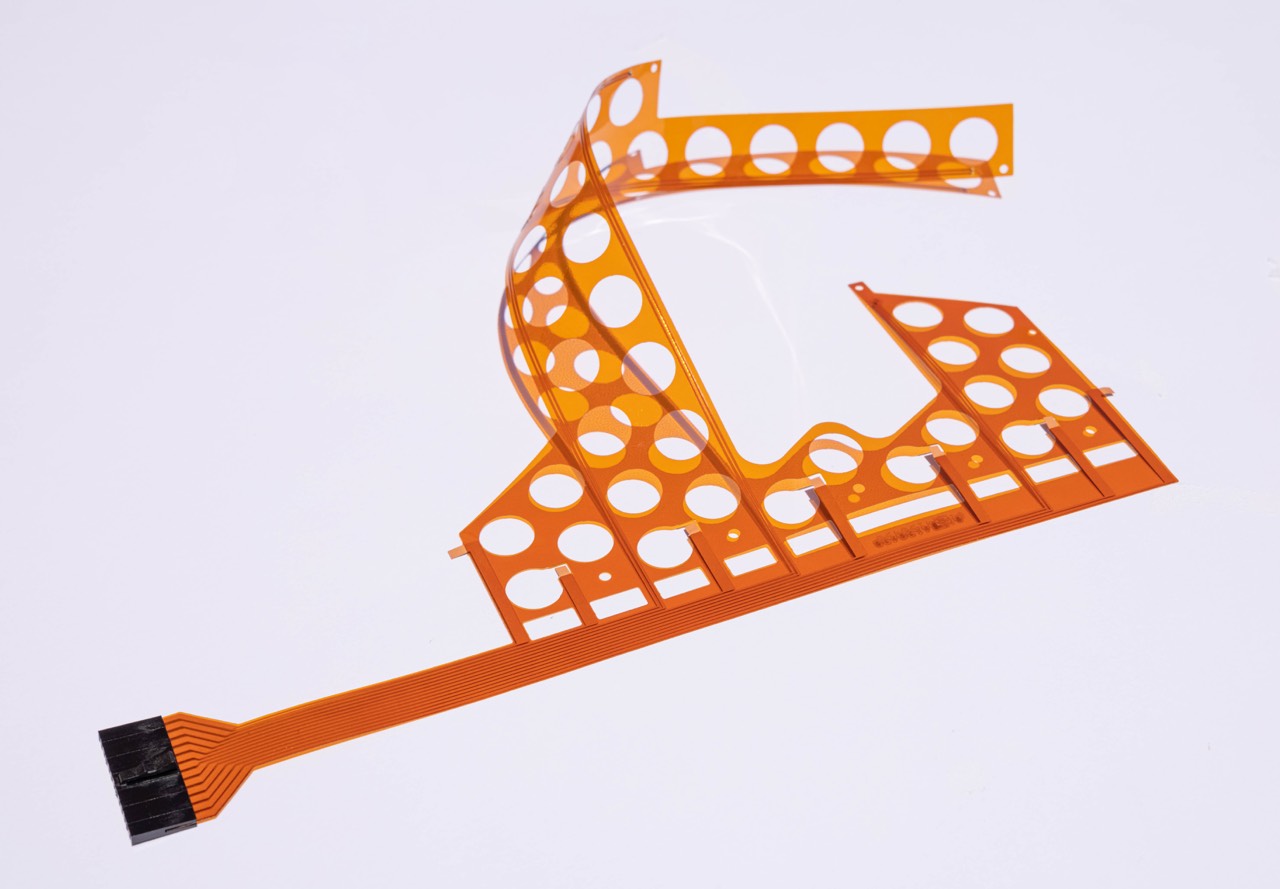

The current market demand is increasingly large FLEX PCB for the interconnections for the battery pack.

These flex pcb have also the function of the temperature monitoring inside battery pack.

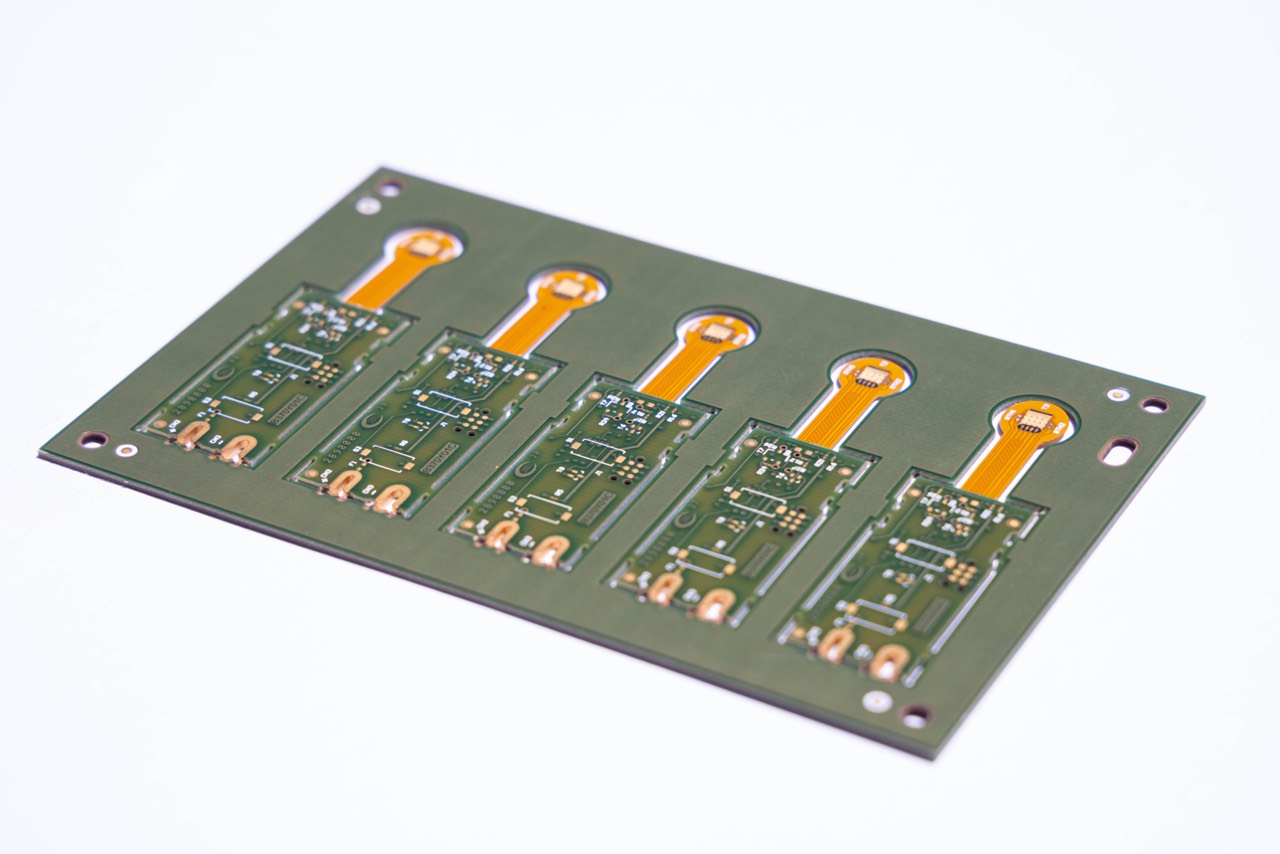

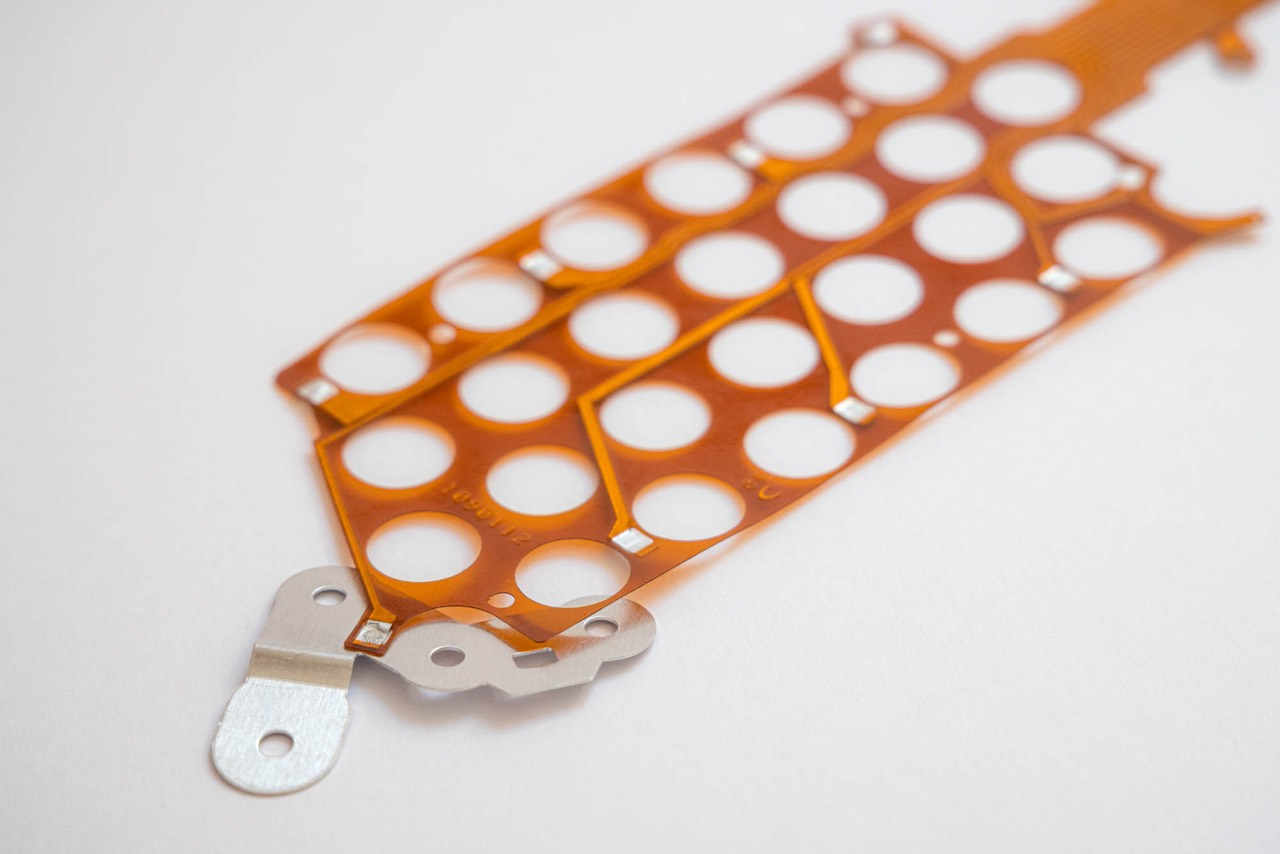

Hence the need to solder electronic components, such as the NTC, fuses, connectors and metal contacts tabs, also with specific resins, adhesive tapes, thermal pads and reinforcements.

In particular, the metal contacts tabs can also be obtained directly from the copper traces of the PCB.

This solution has been developed by Cisel since several years and is already adopted by many customers.

Cisel has invested in customized production machines and SMD assembly lines; we can currently accommodate requests for FLEX pcb up to 2 meters length.

Next step, FLEX PCBs longer than two meters assembled with SMD components.