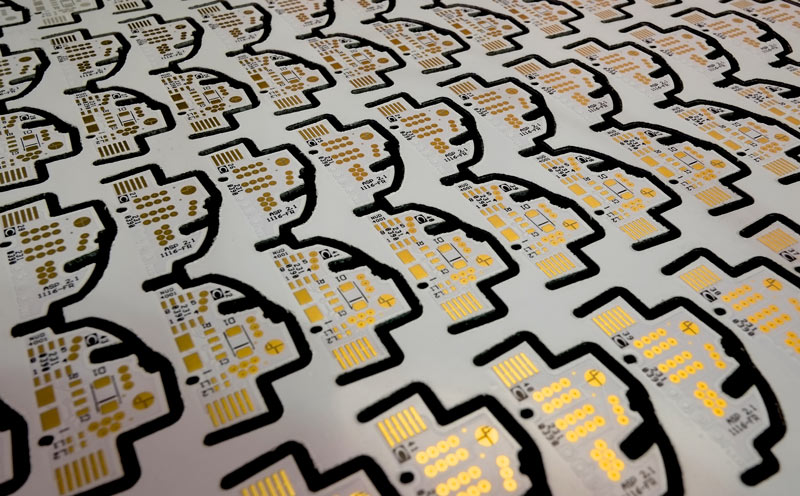

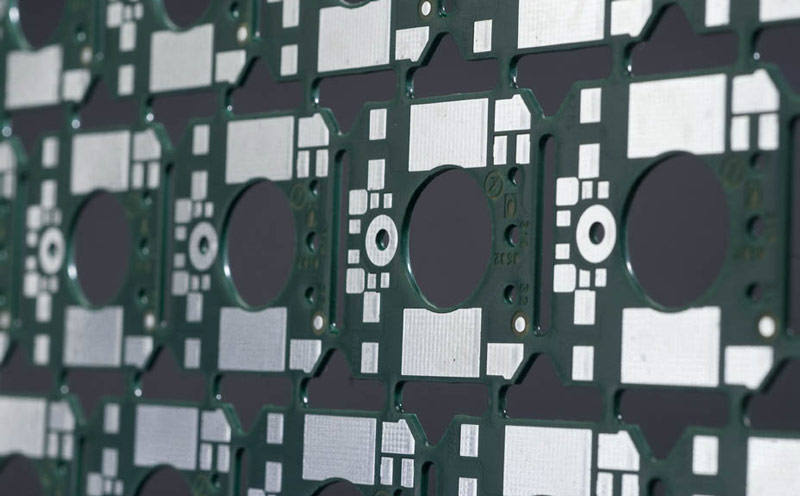

Dissipating materials such as Aluminum and Copper, are also used directly in the production of PCBs with the "IMS" technology.

This technology finds its main application in Industrial lighting, automotive as well as in the sector of adapters / power supplies for electric machines, where a considerable dissipative capacity is required.

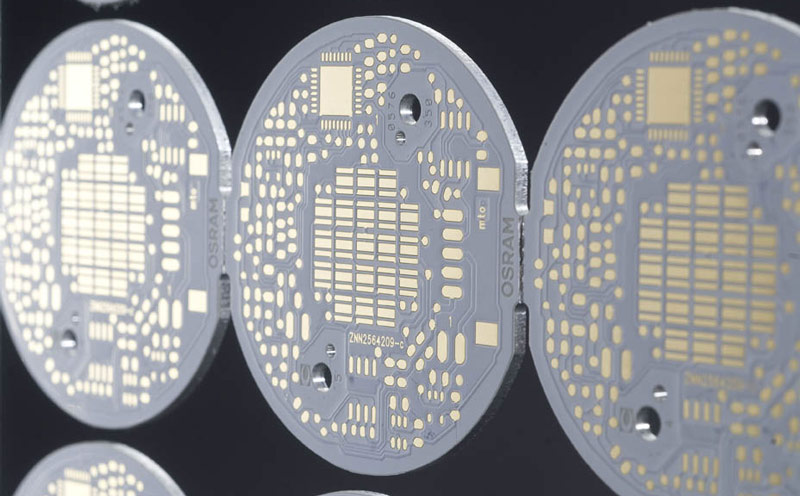

Although the specialized market offers a wide range of products of this type (from 0.5 w / mk to 15 w / mk), Cisel has studied and developed its own material called "Thermal E" which is a valid alternative to existing products both in terms of competitiveness and performance.

Thanks to Thermal E, Cisel is able to supply aluminum printed circuit technology also in double-sided and multi-layer versions with plated through holes.

Thermal E is UL approved for some versions and used and approved by the Automotive market since 1998.

Metal core pcb - Technical details

Tipology

- Single side

- Double Side PTH (Plated Through Hole)

- MLB

- Aluminium Flex

Base Material (from 0,5W/mK up to 12W/mK)

- Alu Dieletric copper

- Alu Ceramic copper

- Alu Flex

- Copper ceramic copper

- Copper Dieletric Copper

Copper Finishing

- OSP

- Chemical Tin

- Chemical Silver

- Chemical Ni/Au

- Chemical Ni/pd/Au

- Electrolytic Tin

- Electrolytic Ni/Au

- HASL

- Carbon Paste